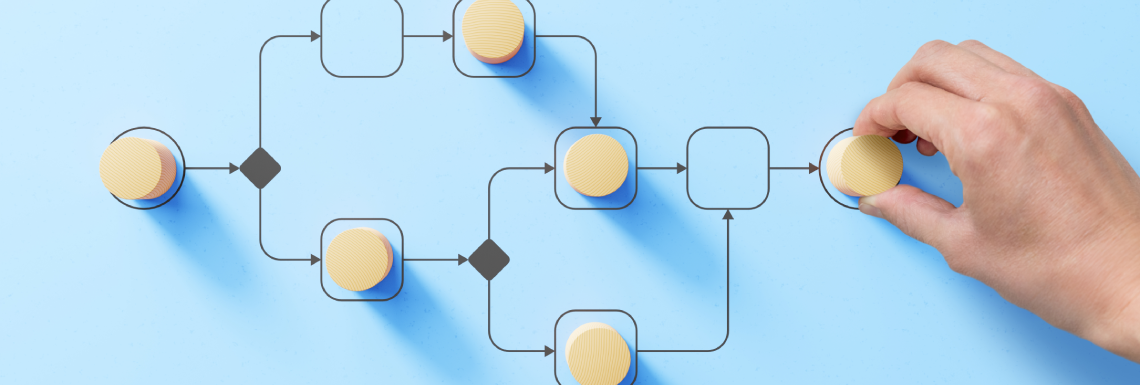

Unlocking Quality and Efficiency: Understanding Process Analytical Technology (PAT)

Introduction to Process Analytical Technology (PAT)

Process Analytical Technology (PAT) is a transformative methodology developed to enhance the quality and efficiency of manufacturing processes, particularly within the pharmaceutical industry. Initiated and defined by the United States Food and Drug Administration (FDA), PAT serves as a framework for real-time monitoring and control of critical production parameters, enabling manufacturers to produce safer, more consistent, and higher-quality products. [1] [2] [3]

Key Concepts Behind PAT

PAT is centered on two essential concepts: Critical Process Parameters (CPPs) and Critical Quality Attributes (CQAs) . CPPs are the variables related to equipment and process conditions that can impact the final product’s quality. CQAs are the defining characteristics of the product that must be consistently achieved to ensure safety and efficacy. [2] [1]

By continuously measuring and controlling CPPs, manufacturers can maintain CQAs throughout production. This approach marks a shift from traditional batch manufacturing to more dynamic, continuous processes, reducing waste, minimizing risks, and enhancing operational agility. [3]

PAT Tools and Technologies

The PAT toolkit encompasses a diverse range of technologies and methods, including:

- In-line and On-line Sensors: Devices such as spectroscopic and chromatographic analyzers provide real-time data on process conditions, enabling immediate intervention when deviations occur. [1]

- Process Control Systems: Automated systems analyze data and adjust process variables to maintain optimal conditions.

- Multivariate Analysis Tools: Advanced analytics interpret complex data sets, supporting better decision-making and process understanding. [5]

- Knowledge Management Platforms: Centralized databases aggregate process data for ongoing improvement and regulatory compliance.

These tools must be accurate, robust, and repeatable, and their selection depends on the specific process and desired outcomes. [3]

Benefits of Implementing PAT

Adopting PAT delivers substantial advantages, including:

- Real-time monitoring of production processes, allowing for immediate corrective action.

- Reduced risk of product recalls or failures by ensuring quality is built into every stage of manufacturing. [1]

- Enhanced efficiency and yield, as continuous feedback minimizes over-processing and waste. [2]

- Lower operating costs through optimized resource utilization and reduced material usage. [3]

- Improved regulatory compliance and risk management. [4]

Case studies have shown that companies integrating PAT often experience notable improvements in product consistency and operational flexibility. For example, during the COVID-19 pandemic, rapid scale-up of vaccine production was facilitated by PAT-based process controls. [3]

Step-by-Step Guidance for PAT Implementation

To successfully adopt PAT in your organization, follow these actionable steps:

- Conduct a Process Assessment: Identify your product’s critical quality attributes and map out the key process parameters influencing them.

- Select Appropriate PAT Tools: Evaluate your manufacturing setup and choose sensors, analyzers, and control systems that are fit for purpose. For detailed technical comparisons, consider referencing guides from reputable suppliers or industry publications. [1]

- Integrate PAT Technologies: Install your selected technologies in-line or on-line where real-time data collection is possible. Ensure that the technology meets accuracy and robustness standards required for regulatory compliance.

- Develop Data Management Strategies: Implement platforms for aggregating and analyzing process data. This supports both continuous improvement and regulatory documentation.

- Train Personnel: Ensure that staff are educated in PAT principles, technologies, and troubleshooting procedures. This may involve attending industry seminars or working with technology providers on customized training programs.

- Establish Monitoring and Reporting Protocols: Define procedures for reviewing process data, setting alarm thresholds, and documenting corrective actions.

- Engage with Regulatory Agencies: Maintain open communication with regulators, ensuring your processes meet current standards and expectations. For specific guidance, consult the FDA’s published framework and updates.

For organizations new to PAT, partnering with experienced technology vendors and participating in professional networks can accelerate adoption and reduce potential challenges.

Challenges and Solutions in PAT Adoption

While the benefits are clear, implementing PAT presents several challenges:

- Complex Integration: Merging new technologies with legacy systems requires careful planning and may necessitate phased adoption.

- Regulatory Uncertainty: Evolving standards can make compliance complicated. Stay updated by regularly consulting FDA resources and industry best practices. [2]

- Knowledge Gaps: Staff may lack expertise in advanced analytical methods. Invest in ongoing training and consider hiring specialists.

- Cost Considerations: Initial investments in PAT infrastructure can be significant, but long-term savings often justify the expense.

Some companies have overcome these challenges by starting with pilot programs in one manufacturing line before scaling up across the organization. [5]

Alternative Approaches and Future Trends

Although PAT is widely recommended, alternative methods such as traditional batch testing, at-line or off-line analyzers, and manual process control are still used in some sectors. However, these approaches generally lack the efficiency, accuracy, and regulatory advantages of PAT. [3]

The future of PAT points toward greater automation, integration with artificial intelligence (AI) for predictive analytics, and increased adoption of continuous manufacturing technologies. Staying informed on these trends can help organizations remain competitive and compliant.

How to Access PAT Resources and Opportunities

To access PAT solutions and guidance:

Source: ideacompiler.com

- You can consult the official FDA website and search for “Process Analytical Technology” to review regulatory frameworks and guidance documents.

- Industry associations like the International Society for Pharmaceutical Engineering (ISPE) offer educational resources and networking opportunities.

- Technology vendors such as Mettler Toledo, Thermo Fisher Scientific, and Hamilton Company provide product information, technical support, and training. Visit their official websites and use the search term “PAT” to find the latest offerings.

- For academic research and case studies, PubMed and other scholarly databases are valuable resources. Search “Process Analytical Technology” for peer-reviewed articles and reviews.

- If you require personalized guidance, consider engaging with a process engineering consultant or attending pharmaceutical manufacturing conferences.

When seeking support or solutions, always verify the credibility and accessibility of the resources. Use official channels and recognized industry organizations to ensure the reliability of information and services.

Source: venngage.com

Summary and Key Takeaways

Process Analytical Technology is redefining quality assurance and efficiency in pharmaceutical manufacturing worldwide. By leveraging real-time monitoring, advanced analytics, and continuous improvement strategies, organizations can achieve safer, more consistent products and drive operational success. Whether you are initiating a PAT program or expanding an existing one, thorough planning, ongoing education, and engagement with trusted resources are essential for maximizing benefits and maintaining compliance.

References

- [1] Mettler Toledo (2025). Process Analytical Technology (PAT) – Enhance Quality and Efficiency.

- [2] Wikipedia (2024). Process analytical technology.

- [3] Hamilton Company (2025). What is Process Analytical Technology (PAT)?

- [4] Thermo Fisher Scientific (2025). Process Analytical Technology | PAT Testing.

- [5] PubMed (2006). Process analytical technology in the pharmaceutical industry.

MORE FROM nicoupon.com